Description

Product details

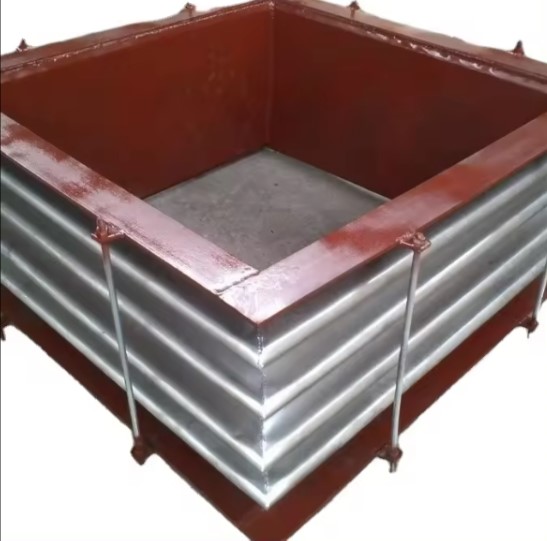

Expansion Bellows by Excel Bellows: Superior Flexibility for Industrial Applications: Expansion Bellows are essential components designed to absorb dimensional changes and movement within piping and ducting systems caused by thermal expansion, vibration, and mechanical stress. At Excel Bellows, we manufacture high-quality, durable expansion bellows engineered for demanding applications across industries, such as power generation, oil & gas, petrochemical, steel, and water treatment. Our products provide essential flexibility, longevity, and reliability, helping industries maintain system integrity and reduce maintenance costs. What Are Expansion Bellows? Expansion bellows are flexible connectors composed of multiple layers of materials such as metal, rubber, or fabric, designed to accommodate different types of movement—axial, lateral, and angular. They relieve stress on system components by expanding, contracting, or flexing, making them ideal for environments with varying temperatures, pressures, and mechanical loads. Key Specifications of Expansion Bellows: Sizes: Available in diameters from 1 inch to 160inches (custom sizing upon request). Temperature Range: Designed to withstand temperatures from -50°C up to 2000°C, depending on the selected materials and specific application. Pressure Ratings: Suited for applications with pressures ranging UPTO 100 bar or more, depending on configuration. Material of Construction (MOC): Stainless Steel (SS304, SS316, SS321, etc.) for corrosion resistance and high-temperature applications. Inconel and Hastelloy for extreme conditions with high chemical exposure. Rubber and Fabric for flexible, low-pressure applications in low to medium temperatures. Key Features of Expansion Bellows Flexibility: Expansion bellows allow for axial, lateral, and angular movements, helping systems manage thermal expansion, vibration, and misalignment. Corrosion Resistance: High-quality materials like stainless steel or specialty alloys provide superior corrosion resistance, even in harsh chemical or weather-exposed environments. Pressure Handling: Designed to accommodate pressures from vacuum to high-pressure systems, depending on application requirements. Customizable Design: Excel Bellows offers tailored expansion bellows to meet specific requirements, with options for material, shape, size, and pressure rating. Easy Installation: Lightweight and flexible, expansion bellows are easy to install and integrate seamlessly into complex piping systems. Applications of Expansion Bellows: Expansion bellows play a critical role in maintaining structural integrity across various industries by handling temperature variations, pressure changes, and vibrations. Key applications include: Power Generation: Used in boilers, turbines, and exhaust systems to handle high temperatures and prevent damage from expansion. Oil & Gas: Protects pipelines from stress due to temperature fluctuations and pressure changes, reducing wear on critical components. Petrochemical Plants: Accommodates thermal movement in piping systems that transport volatile chemicals and gases. Steel & Cement Industries: Applied in high-temperature ducting and piping systems to absorb thermal expansion and vibrations. Water Treatment: Handles temperature-induced expansion in pipelines transporting water or other fluids in treatment facilities. HVAC Systems: Ensures duct flexibility and minimizes vibration transmission in heating, ventilation, and air conditioning systems. Maintenance and Installation Tips: To extend the service life of expansion bellows and maintain optimal performance, follow these maintenance and installation guidelines: Regular Inspections: Check for signs of wear, corrosion, and deformation, especially in high-stress environments. Proper Alignment: Ensure proper alignment during installation to prevent undue stress and premature wear. Cleaning and Protection: Remove any debris, dust, or foreign materials that could cause abrasion, and apply protective coatings where necessary. Routine Maintenance: Perform regular maintenance checks to identify early signs of damage, preventing costly system downtime. Why Choose Excel Bellows? Excel Bellows is a trusted name in manufacturing expansion bellows tailored to industrial specifications. We prioritize quality, reliability, and customer satisfaction, ensuring that our bellows deliver outstanding performance, longevity, and cost-efficiency. With customized solutions, competitive pricing, and expert engineering, Excel Bellows is the ideal partner for your expansion needs. Expansion bellows manufacturer Industrial expansion bellows Flexible expansion joints High-temperature expansion bellows Custom metal bellows Expansion joints for power plants Thermal expansion bellows Corrosion-resistant bellows Expansion bellows for oil & gas Durable expansion bellows for industrial use Choose Excel Bellows for your expansion bellow requirements and benefit.